Enapart, with a presence in 14 countries, sources products from around the world to offer you the best possible prices as a local reseller in the France . To acquire the best quotation for your desired product, kindly contact us through e-mail or our contact form.

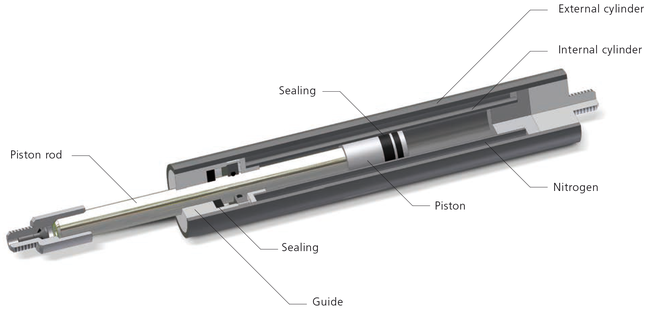

Tension springs work in the reverse way to compression springs, meaning that the gas pressure in the cylinder pulls the piston rod inwards. When an opening is closed, the tension spring thus supports the manual force. A tension spring is an enclosed, maintenance-free element. It consists of a pressure tube and a piston rod with piston. In addition, a seal to prevent possible loss of gas is fitted at the piston rod guide. The tension spring is fitted with compressed gas – nitrogen – which provides the spring force. In the unpressurised state, the piston rod is always retracted. Pulling out the piston rod reduces the volume in the cylinder and the gas is compressed. This creates an increase in force (progression) for the spring, which depends on the diameter of the piston rod and the volume of the cylinder. The piston has a small opening (nozzle), through which the gas can flow, thus allowing the piston rod to move at a defined speed. The cross-section (diameter) of this opening defines the degree of damping of a spring.

Tension gas springs are used in any situation in which normal gas compression springs cannot be used for space reasons. They support manual force when opening covers which have to be pulled upward to open them. This option is found, for example, in the escape hatches of lifts. In addition, tension springs are used if covers have to be held up while open, as is the case, for example, with desks with a lifting work surface.